Enhancing Soil Stability with Dynamic Replacement Technique

Dynamic replacement is a ground improvement technique that reinforces fine grained soils with a network of dynamically pounded pillars.

Compaction or Dynamic Replacement?

If the ground cannot be dynamically compacted directly due to high fines content within the soil, a fill material must be added. The incorporation ratio is generally between 10 and 15%, and is higher than that of stone columns.

Dynamic replacement Implementation

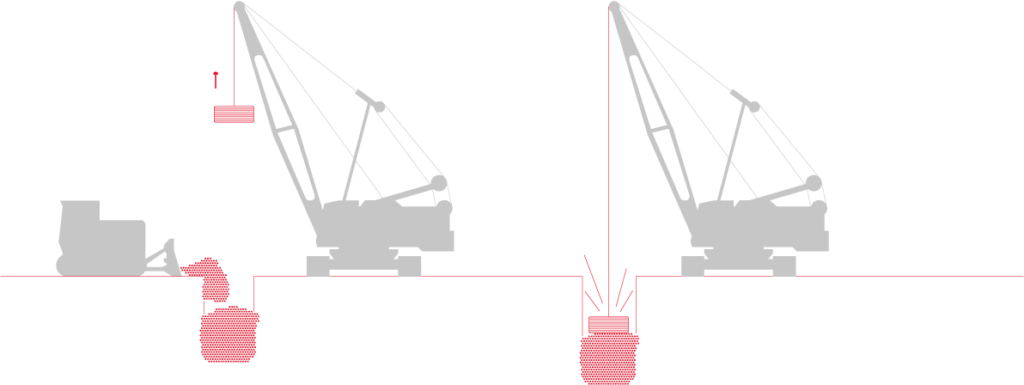

The Dynamic replacement technique can be carried out with or without pre-excavation. Pounding and filling of the reinforcement pillars alternates accordingly during execution. The material incorporated is either placed over the whole treatment surface prior to pounding and pushed into the pillars during the project, or stored at a regular intervals around the worksite and directly incorporated in the pillars.

Dynamic replacement Advantages

The technique is particularly well suited to areas under high load (high backfill, storage tanks, etc.) and also allows for rapid drainage of the ground.

Dynamic Replacement FAQ

No, because the initial pounding of the platform is generally sufficient to form the crater that initiates the dynamic replacement pillars. After filling this crater, pounding drives the “compacted plug” into the soil, which then serves as the basis for the formation of the rest of the pillar.

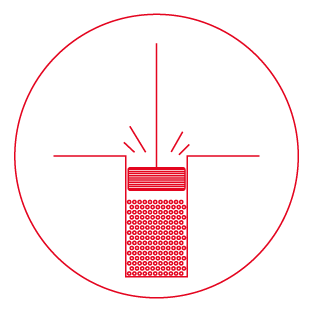

The large diameters (2 to 2.5 meters) and low slenderness ratio of dynamic replacement pillars make them suitable for treating very loose, waterlogged and highly organic soils. If need be, preloading can be carried out to reduce residual settlement.